微孔加工

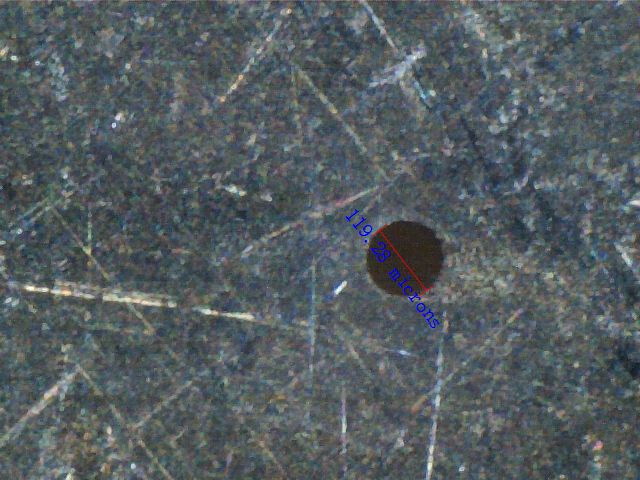

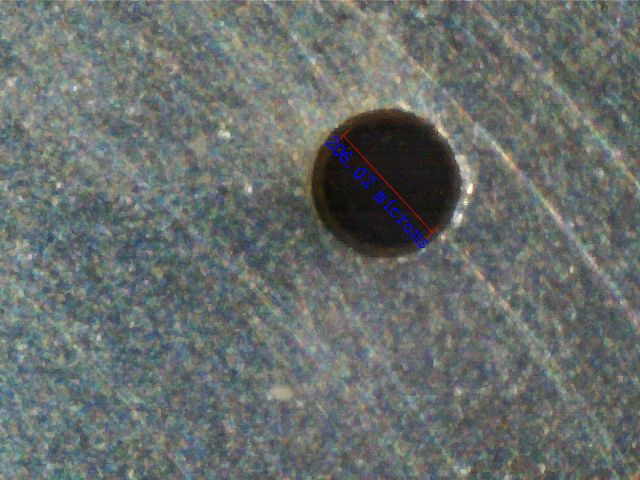

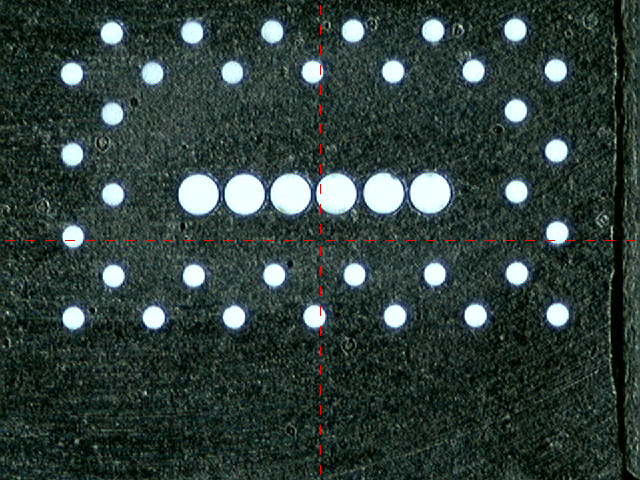

微孔加工,一般指加工孔直径在0.5mm以下的微小孔加工,微孔结构已广泛应用在航天、航空、军工、机械、自动控制、化学纤维、光电仪器仪表、日用等行业和一些尖端制品中。微孔加工的效果主要取决于孔的直径、深度、工件材料、设备要求、精度、粗糙度、光洁度、同心度及微孔尺寸。

规格:

加工材质:不锈钢、铝、铜、陶瓷、玻璃、硬质合金、耐磨材料等;

孔径:0.01-0.5mm,0.2mm以下的微孔加工适合单孔少量孔加工,0.2-0.5mm的微孔加工可以是微孔板;

深径比:-30,孔径小于板厚的适合加工微孔板,深径比<5的适合为小孔加工,深径比>5的工件为细长小孔加工;

光洁度:0.15mm以下的小孔较难研磨,0.15mm以上的孔较易研磨;

加工精度:+ -0.005mm;。

应用领域:

金属码盘、雾化片、微孔过滤网、微孔筛网、油嘴、光栅、光阑、透光片、喷嘴、

Micro machining, generally refers to the tiny hole machining hole diameter 0.5mm or less, pore structure has been widely used in aerospace, aviation, military, machinery, automatic control, chemical fiber, optical instruments, household products and other industries, and some tips in. Micro machining effect depends hole diameter, depth, workpiece material, equipment requirements, precision, roughness, smoothness, pore size and concentricity.

Specifications:

Processing material: stainless steel, aluminum, copper, ceramic, glass, carbide, wear-resistant materials;

Aperture: 0.01-0.5mm, microporous 0.2mm hole for a small amount of processing following hole machining, 0.2-0.5mm of micro machining can be microplate;

Depth to diameter ratio: -30, less than the thickness of the aperture for processing microplates, deep-diameter ratio of <5 is suitable for machining holes, depth to diameter ratio> 5 piece elongated hole machining;

Finish: polished orifice 0.15mm or less difficult, 0.15mm or more holes easier grinding;

Precision: + -0.005mm ;.

Application areas:

Metal code disc, fogging films, filters, screens, glib, grating, aperture, light pieces, nozzles。

|

|

|

|